A common theme retailers report is shoppers will buy what they perceive to be clean and safe, and products focused on building immunity. Bringing prepared foods departments back to life, with made-to-order service menus, hot- and cold-food bars, and self-service bulk foods departments, remains an open question, answered only with trial and error, and time.

We want to thank the retailers who generously shared their efforts to remake their businesses in a COVID world. Here follows interviews from retailers on the East and West Coasts.

Mid-Atlantic Single-Store Natural Retailer

Owner: “There are several positives coming out of COVID. It gave us a breather and allowed us to focus deeply on our prepared foods program and become more efficient. We have a scratch bakery and kitchen, which drove our business. It ran well, pre-COVID, but wasn’t profitable. If ‘normalcy’ ever returns, we’ll be more efficient, better operators.“We did a good job, but labor and administrative costs ate up profits. We had four food bars; hot, salad, meat, and vegan, all self-serve. All of them needed labor runners, to do things like replenish plates, utensils. We had three dishwashers—an expensive part of the kitchen, to run the bars. We made all our sandwiches to order, and had a large menu of build-your-own bowls, also service. None of these was profitable.

“Now, the scratch items we do are simpler. We put in inexpensive four-foot hot cases for pizza, chicken wings and nuggets, all in plastic containers. Those changes stopped the bleeding. And we plan on reinventing again later as customer confidence returns. We love to make and bake food, but we just weren’t super-efficient.

“Our adjustments included bringing in more par-baked goods. Also, we adjusted the price point to be closer to ‘grocery’ with vendor-supplied food. If you have a good third-party wholesale prepared foods vendor, it becomes like a grocery item, with a 35% gross profit margin.

“We are negotiating with a natural products kitchen already serving several natural foods stores, with ingredient standards that align with ours. The challenge is shipping refrigerated stuff LTL (less-than-load by common carrier). The bakery and food items are tasty, and we’d ship twice per week.

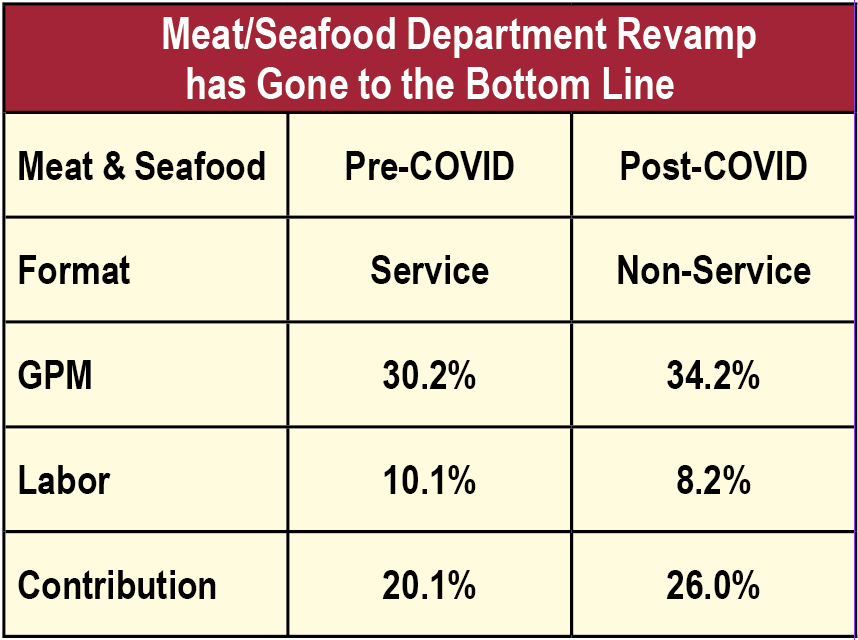

“We think we can work it out. What this allows us to do is to focus on the menu items that we do best, and that are more profitable for us. We kept the hot and salad bars. We scrapped the meat and vegan bars, which freed up space. In their place we put a couple of Hussmann coffin refrigerated cases for grab-and-go. We also revised the meat and seafood service counters, which allowed us to add more frozen and refrigerated meat and seafood choices, and to close the service area. We did all this last summer, which reduced shrink and labor.

“Customers have responded well, relieving our worries about changing the customer experience by removing some service areas. Our customers know we are always changing and adding. We added a ringer button for customers to alert us when staff is not on the floor in the prepared foods area.

“Customers have responded well, relieving our worries about changing the customer experience by removing some service areas. Our customers know we are always changing and adding. We added a ringer button for customers to alert us when staff is not on the floor in the prepared foods area.“We estimate our capital expenditures for these changes were $50,000. Since the remodel, our annualized incremental realized profit is $39,000. So, we’re seeing a return on our investment in just over 15 months.

“Overall, we have become more consistent, without the variability of the larger menu, and the staffing challenges of turnover in the kitchen. Prepared foods were 25% of sales, but weren’t profitable. Overall, we will downsize some, not a lot. Our prepared foods are still a customer draw. We combined kitchen and bakery management, which has saved labor, and allowed us to hire a better-skilled food service manager. We believe we are meeting customer expectations. And it has lowered stress levels in the store, overall, as well.”

West Coast Multi-Store Natural Retailer

Owner: “We haven’t really begun to implement the post-COVID changes we want to make, but feel like it should begin in the next several weeks. From the virus standpoint, our county looks really good, with active cases way down; 150 now, down from the low thousands, over the last several months. We were having trouble getting under 300, but now we are. With about 260,000 people in the county, that means our case load is really low. We have four people in ICU, down from as many as 10. The deaths have not changed, so those that go into ICU are coming out. We are stable county-wide at 170 deaths total.“Our health department has moved our status to ‘red,’ which is the next to least restriction level. Yellow is the least restrictive, and if we continue to maintain the lack of new cases over next two weeks, we will move to yellow. We could open up our outdoor seating areas for customers. We are at least a week away from doing that, as we now use that area for staff to safely distance themselves while on break. We have had that area cordoned off from the public for many months now. As the weather gets better, we have had to run a customer or two out of the area. We are talking about opening the other side of the store for customer eating areas. We hope to take some of the tables and move them out to the sidewalk for customers, so we can still maintain the staff outside break area.

“Inside the stores, we are still limiting number of staff in certain areas. We plan to clean up the signage telling customers where to stand, and about social distancing. We’ll be getting those out of the windows. We’re not going to immediately eliminate all of it, but begin to reduce it.

“At the moment, we line people up to be checked out, and help them stand six feet apart. Where we have them standing snakes them through a bunch of different products on your way out, in these shopping zones. For impulse housewares sales, it’s going pretty darn well. It’s not what we want, because in order to do this, we need an extra employee to police it; what cashier is ready, what line to get into. We want to shift some of that labor back to normal grocery focus.

“We also have somebody checking you into the store, and on the way out. Our entrances and exits are all one way now to eliminate cross-pathing, so we need someone at each door. I give that not too many more weeks, unless the COVID numbers spike again. When I visit other stores [out of state], I don’t see any of that going on. People are at the checkout stand, and there are not others behind them trying to load their shopping onto the belt. People seem to respect that the cashiers have to wipe the conveyor belt down before I put my stuff on it.

“In the bulk department, we are still servicing all items from the bulk gravity feed bins and prepacking all other items from food bins. We have an employee who takes customer gravity-feed item orders. The customer fills out a small order slip and then continues shopping for produce and other store departments. When they come back, staff has bagged up their bulk order. For all other bulk items, it all is being packaged off site.

“We’ve asked the health department about the timing of opening up the bulk department. At what point is it going to be okay? If not, we want some long-term guidance. We have the same question about our salad bar, and hot bar. What is their feeling about opening that up in the future? So far, they are buying time on getting back to us on answering these questions.

“We have no plans to open the salad bars. For our hot and cold food bars that were previously self-serve, we have it all in prepackaged form on those same bars. We want to do a quick, four- or five-questionnaire for customers, asking them where their heads are. How do they feel about using the same community serving spoon? Would they put on gloves? What if we provide the ability for customers to wash hands before and after? The whole idea of self-service of anything is going to be an interesting new reality for grocers to deal with or shift away from.

“We need to figure out if there is business to be had on the bars. Nationally, we hear a lot of conversation about it not coming back. But maybe our loyal customers would. We think there is a psychology of customers, some who are just not going to visit self-service bars anymore. We are just going to trial things out to see what works. We have some new ideas as well. Will they trust a new, reusable, returnable container framework of self-service bars?

“But we believe strongly it is a priority for us to get out of all the extra packaging. So, we are considering developing a re-use, deposited system. We would create a place for dirties to come back into, and where customers can grab a fresh one.

“Right before COVID, we were putting that in place. We had just received a $20,000 order of stainless-steel deposited dishware. Really nice, with lids, to begin a container exchange system, with a standard container design. We were hoping to use this system throughout town so restaurants and even other grocers in town could participate in the program, all pre-COVID. We think this is probably a startup third-party service, a separate business that maintains this service for stores and restaurants.

“There has been a glass jar supply issue. We can’t get them. With the lockdowns, people did canning and food experiments at home. We had to go back to putting product in paper. We found a new line of some glass, not Ball or Mason, a different quart, pint, single-serve, and other sizes, for soups, sauces.

“We wanted to create an incentive for people to go through their pantries and bring jars back. We knew there were thousands of jars out there. And now, people are returning the containers. We had a $1.50 deposit for a pint or quart jar, or a milk bottle, regardless. That was fine. Only non-regular customers, who were passing through and couldn’t bring the jar back, had a problem. So, we got the new jar supply, and moved the deposit to $3.00 per jar, and we required the lid coming back too.

“And it has worked. We have enough of a flow of returned jars. People who initially paid $1.50 deposit made out well when they got $3.00 back under the new incentive program. We want to lead the way with ‘returnables,’ in common, reusable containers, that multiple businesses, grocery stores, restaurants, could use and begin in a real way to eliminate the single use of anything. We think it is a third-party business, that has space for a scullery and container washing rooms; a new business model. Customers are going to pay for it, but whether they know it or not, they are paying for it now. For example, a 47-cent fold up hinged box; we build that cost into the price of the food they’re buying.” JJ