Richard passed last April, but his vision lives on. Talk to anyone at the company and at some point the Golden Rule will be invoked. “Do unto others as you would have done unto you.”

The Richard family still owns NOW but at the helm is Jim Emme, a farm boy who joined as a plant manager 23 years ago from food giant Pillsbury. “Elwood Richard’s vision was easy to buy into. So were his ethics and character,” Emme recalls. “Giving people a fair shake. Making sure people got a good value. If we made a mistake, make it right.”

The farm boy also brings a background in mergers and acquisitions. Emme knows he’s steering a coveted debt-free and increasingly international ship that’s pulling in about a half-billion in annual sales. When news broke that Atrium Innovations and its Garden of Life brand would be acquired by Nestle for $2.3 billion, he had no fewer than 50 inquiries in the first 36 hours. He responded to none of them.

“The Richard family is committed to sustaining NOW as an independent company. It allows us to make decisions for the right reasons,” Emme says. “We are a for-profit company, but we probably invest more in our people and capital expenses than many companies in our industry.

“We may choose to make less money one year to invest in expansion. We may choose not to sell products because they don’t meet our standards,” Emme continues. “Being a family-owned business puts us in a position of trust. We’re investing in the quality of our products and in the skills of our people.”

Every extended family member owns shares in the NOW Health Group and many are on the board or a board committee. They were raised to view the company as a responsibility, not a cash cow. The odds of taking it public are nil.

Cause for CelebrationTo celebrate its 50 years, NOW is giving back in a big way — $500,000 in prize money for consumers who find one of 50 Gold-capped bottles carrying a Willy Wonka-inspired golden ticket inside that will earn each bearer $10,000. Retailers and their staff are eligible to play along.

Amber Cerda, senior marketing manager, said 1 million Gold Cap supplement bottles are being distributed within the 50 states, covering 50 SKUs and timed to coincide with traditional sales patterns. It all should be in distribution by the end of Q2. The promotion runs through Oct. 1 and will receive unprecedented consumer advertising support from NOW, driving customers to stores to look for the product.

The promotion’s companion website www.nowfoods.com/celebratenowcarries a store locator tool for consumers to find out which stores carry the products. “We’re hoping this will be a way to drive excitement in stores as well as traffic,” Cerda says.

The company’s charitable giving will also increase by 50% this year — adding $1 million to normal giving. NOW’s been a supporter of Vitamin Angels from its inception and leans to charities it considers “self-enabling,” teaching recipients skills they need to take care of themselves going forward. Employees have a say in which charities are chosen and decisions are made by a committee comprising Richard family members and members of the leadership team.

As a privately-held company, NOW keeps sales specifics close to the vest. Dan Richard, son of Elwood, who as SVP of product and sales came up with the idea for the bottle promotion, says NOW is experiencing 20% growth internationally and global sales represent more than 20% of its business while no one product accounts for more than 3% of sales. “We’ve had a seven-year run of double-digit growth and international has been our fastest-growing segment. International is where our growth is going to happen. We see that as our future,” Richard adds.

Last February, NOW opened a new 200,000-square-foot distribution facility in Roselle, IL — its third U.S.-based facility joining ones in Bloomingdale, IL, and Sparks, NV. Among its features is a three-story, high-velocity picking module designed to drive higher order output that is scalable for future growth.

“When I came onboard with NOW, Elwood and his brother Lou were trying to bring more manufacturing in-house,” Emme recalls. “Back then, most of their products were contract-manufactured. In the mid 1990s, sometimes the quality was good and sometimes it was terrible.”

“Life is good relative to our past,” admits Richard. “We’re not concerned about an audit or a surprise TV camera. Those used to be concerns. No longer.”

Quality Attracts QualityOne of NOW’s unique assets is Aaron Secrist, who joined NOW in 2011 and was recently promoted to VP of quality and regulatory affairs. He directs the scientists and lab workers whose efforts ensure the 1,500 SKUs and 70 new SKUs introduced monthly are good enough for his own family.

“I joined NOW because I saw an organization that was truly committed to doing the right thing for the right reasons,” says Secrist, who conducted GMP audits for the Natural Products Association and brought 20 years of dietary supplements industry experience. “Almost 10 years ago, before I started working for NOW, I did a compliance audit and found some facility-related things that needed to be fixed. The fixes were not inexpensive and were not easy to do.”

Secrist was expecting the usual pushback from management. He was impressed by what happened instead.

“The CEO of NOW along with Jim Emme, who was the COO at the time, sat down with me for over an hour after I finished the audit. They wanted to know everything they needed to do and how they benchmarked with other companies. This was unique for the executives to take time out of their busy schedules to understand what needed to be done and to commit to me personally that they would make the needed changes.

“I came back a short while later and all of the facility changes were done just as they said they would be. I was so impressed that I remember thinking to myself, ‘This is a company that is truly dedicated to quality. This is a company that I could work for.’ A few years later, they offered me a position and I have enjoyed every minute that I have been here.

“One thing that makes NOW different from other companies is we are 100% committed to getting it right,” Secrist adds. “Most companies do some sort of skip lot testing but NOW tests every lot for every label claim we make…We certainly are not perfect, but I can honestly say that every single day when I walk out the door, things are a little better than they were when I came to work in the morning.”

“We’re very conservative in our approach to what we’ll do,” says Emme. “We’re rule followers. We always comply. With that we don’t have too many surprises.”

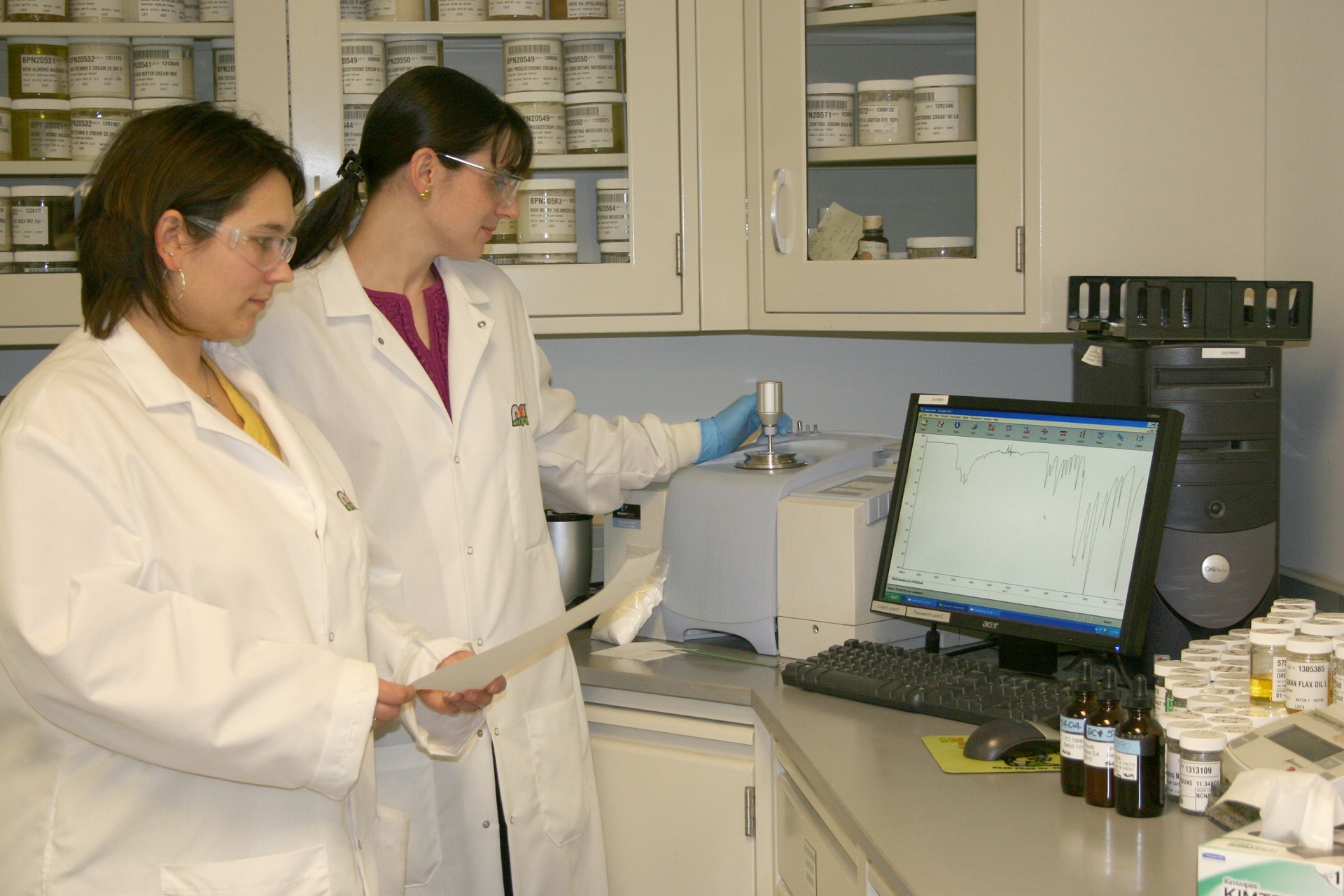

Secrist sees that as a strength in a world with an increasingly educated consumer population demanding transparency. NOW hosts virtual tours on social media and every second Wednesday conducts hour-long on-site visits in Bloomingdale that average 10 to 20 people each month.

“A lot of things go on here that we don’t tell people,” Richard says. “We’re a manufacturing and quality machine. We’ve got a lot of people who are running a lot of lines. Over 150 employees work in our quality area. They’re testing, sampling, doing the documentation work. There’s endless work we do that people wouldn’t recognize. You can’t look at a package and see that.”

Still, “I can imagine a day in the not-too-distant future,” Secrist speculates, “where a consumer could pick up a bottle and by scanning a code on the bottle could take an instant tour of the facility that made it and see where and how the ingredients were grown and processed.”

Secrist understands the fragility of it all.

“The complexity of the global supply amidst geopolitical issues and increasingly unpredictable weather patterns around the world have the potential to disrupt the supply chain in an instant, which always opens the door to the charlatans and shysters,” he says. “Luckily, I work for a company that understands that quality is synonymous with brand protection and I am given the resources I need to stay ahead of these constantly evolving issues.”

Developing Its PeopleNOW employs roughly 1,600 workers and demonstrates appreciation with benefits like educational reimbursement and a quarterly bonus — an additional year-end payment in better years. It’s been voted one of Chicagoland’s best places to work for 10 years running and received national recognition for the past five from the National Association for Business Resources (NABR). Other perks include an in-house wellness center with licensed trainers. Last year, employees got their fitness tracker of choice — either a FitBit or Apple 3 watch. Yes, it makes business sense to keep workers healthy, but Emme seems especially proud that in 2017 for the first time the company received the NABR’s national Best and Brightest in Wellness award.

Average length of employee service is more than nine years. Some people have been with the company upwards of 40.

“I just love the fact we don’t lay our people off,” Emme says. “I love the fact we can provide a good living wage, promote from within when they’re developed. How many people can say their mission is to help people live a healthier life?”

NOW’s also been recognized for environmental sustainability. It has a heavy recycling program and does a lot of volunteer work with local parks and reserves throughout North America. Conservation is a key beneficiary of charitable investment.

The company’s engagement with the communities where it resides helps keep the personnel pipeline going. Sen. Tammy Duckworth was so impressed with the number of women NOW employs as scientists that she started bringing with her on tours a group of middle-school students who are all female science fans and call themselves “Science Chicks.” Some have gone on to become NOW interns.

In Nevada, the company is working with a STEM program to help get students interested in mechanics and science to develop a workforce for its Sparks location. It’s also another way of giving back.

Maintaining the culture is essential to the future success of NOW, Emme believes. “We can hire professionals with a high level of technical skill, but they just can’t get the culture piece. We couldn’t do anything if we didn’t have people who shared our values and our culture,” he says. It’s that Golden Rule.

Emotional intelligence and behavioral testing screens are done that can help find blind spots and help with the onboarding process through customized training. They also help flag people who are too set in their ways. Emme keeps a grid in his office as a reminder that not everyone has the same work style.

Brick-and-Mortar In the DNANOW began as the private label for Fruitful Yield and the company still operates 13 brick-and-mortar stores in the greater Chicago metro area.

“One thing we are still very committed to, even though online sales are growing fast, is the success of brick-and-mortar retailers. It’s in our legacy,” Emme says. “Even though online sales are growing, the reality is the business begins with brick-and-mortar retailers. That’s where consumers get their information. They aren’t going to rely on a Yelp review or an Amazon review. They’re likely going to an independent retailer.

“One of the things we’ve found is the successful independent retailers are the ones that develop trust in their community. They’re almost a destination. The shift online is a global phenomenon. It’s not going away. But we also believe in independents and still do significant business with GNC, Vitamin Shoppe, chains like Natural Grocers, even Whole Foods Market with Amazon acquiring them. We’ve seen steady growth overall throughout the natural chains.”

According to the most recent available SPINS sales data, NOW ranks first in sports nutrition, amino acids, and miscellaneous supplements, in the natural channel and sometimes mass merchandise, too. It holds four of the top 10 positions in carrier oils, including the No. 1 seller almond oil. It’s a close second in the essential oils category.

Company-owned Fruitful Yield stores also serve as a product incubator, test bed and early-detection system for picking up on shifting consumer attitudes.

“We have 55 years of history running retail,” Richard says. “It gives a good clue of what sells in stores, what consumers want, what they complain about. If we want to do surveys on packages or products, we’re able to touch base very quickly.”

Customers have helped NOW grow. In the beginning, the business plan was 100% product and 0% marketing. But as the company started listening to customers, that changed. Customers said the labels were ugly. The company’s now on its 10th generation of labels.

New Products and CertificationsNOW Sports is unveiling a silver foil label this quarter while in the process of getting a third-party certification for its entire line from Informed Sport, a global quality assurance program for sports nutrition products, suppliers and manufacturers. Once those audits are passed, labels will include a steroid-free claim.

“The program certifies that every batch of a supplement product and/or raw material that bears the Informed-Sport logo has been tested for banned substances,” says Secrist. “This gives professional, Olympic and collegiate athletes everywhere the peace of mind they require to be able to take the nutritional supplements they need to be competitive. Each batch of each product will be tested by an accredited third party against the various prohibited substances lists such as WADA (World Anti-doping Association), NFL, MLB, NBA, NHL, MLS, PGA/WPGA, WTA, NCAA. This is a remarkable accomplishment and will give elite athletes worry-free access to the most comprehensive line of natural sports products in the world.”

“I think we’ve been blessed as a business,” Dan Richard says. “From a Christian perspective, we’ve been lucky. A lot of our competitors have messed up. We followed the straight and narrow.”

Emme traces it all back to Elwood Richard that NOW has beat the odds of the family-owned company and is thriving beyond its founding family member.

“The founders of the company need to communicate their vision,” he says. “Elwood was really clear. They have to communicate what the standards will be. Lead by example. Don’t compromise. Reinvest in the business. If you don’t reinvest in the business, you can’t support growth or maintain growth.

“Not only does this have to be done with the outside employees and associates, it has to be communicated and expected of the next generation of the family. If it’s not, then it gets lost.”

Inside NOW’s Quality Control Process

Aaron Secrist, VP of quality and regulatory affairs at NOW, described the details of its manufacturing processes to make sure people are getting what they pay for.“Our testing process really begins at the conceptual phase where we design products that work. We make sure there is solid scientific evidence that the products we design can support the structure/function claims we make about the product.

"Next we ensure the ingredients are safe by doing a full toxicological review of the ingredients and finished product. Once this looks good, we begin to source the ingredients by putting each new ingredient supplier through a rigorous qualification process that includes a thorough review of their food safety plan and often an onsite audit.

"Once we determine they are in control of their processes and that the ingredients they supply meet our specifications and are free from harmful contaminants, we authorize our Purchasing group to procure the material. The Quality and R&D departments put together a master formula and master manufacturing record for each product that gives complete instructions on how the product is to be made in a consistent and reproducible manner.

"Once the raw materials are received, each lot is statistically sampled and tested to make sure it is what it purports to be, that there are no harmful pesticides or residual solvents, that arsenic, cadmium, lead and mercury levels are within normal, safe levels and that there are no harmful pathogens such as Salmonella spp., E coli, or Listeria monocytogenes.

"We also make sure any label claims we plan on making on the finished product will be supported by using the ingredients. Once the incoming raw materials are tested and released by the Quality department, the manufacturing group uses the instructions developed by Quality and R&D, which consist of many in-process checks to ensure that each step is followed exactly as it is written.

"Each step in the manufacturing process incorporates metal detection to ensure that no metal contaminates the product during the manufacturing process. Once the production process is complete, representative samples are taken of each and every lot produced and they are tested for every single label claim made on the product.

Quality is truly a journey and not a destination. There is always more that can be done and NOW is committed to this journey.”

Published in WholeFoods Magazine February 2018