For instance: Did you know that the dietary supplement aisle of your store is ALIVE?

At least part of it is—the probiotic aisle has billions of live microorganisms in every capsule. Jamie Lee Curtis became the probiotic ambassador to many of us, but there is much more to the story. While the concept of probiotics is relatively new to many, probiotics have been in our diet for thousands of years and in our bodies since the beginning of man.

Probiotics are different than most other dietary supplements in that they contain live microorganisms. Though, whether the ingredients in your supplement or alive or not, the condition in which the product is stored is important. Your store and its shelves are temperature controlled, and in the online universe, that’s not the case. Specifically, Amazon’s is not! A natural retailer store shelf is not as likely to receive customer complaints about:

-

-

- Ice packs used in shipping turning to "literal mush" by the time the package arrived in the summer heat, leading the buyer to caution: "I wouldn’t recommend having these shipped, but rather just picked up in store, at least until the Cooler months of the year."

- Vitamins arriving with a "white mold substance on them" and a 2-star review: "I think these vitamins are best bought in stores."

- A "rancid batch" that the buyer said triggered symptoms including bloating, stomach pain, and cloudy urine, followed by "multiple trips to doctor, urologist, CT scan, gastroenterologist, and hundreds of dollars in medical bills." This purchaser warns: "Amazon's quality control with this product is dangerous and can seriously put your health at risk. Buyer beware."

-

Let’s go back to probiotics.

The word probiotic is derived from Latin and means “for life”(1).The International Scientific Association for Probiotics and Prebiotics defines “probiotics” as “live microorganisms that, when administered in adequate amounts, confer a health benefit on the host”(2). These microorganisms, which consist mainly of bacteria but also include yeasts, are naturally present in fermented foods, may be added to other food products, and are available as dietary supplements.

Probiotics are measured in colony forming units (CFU), which indicate the number of viable cells. Amounts may be written on product labels as, for example, 1 x 109 for 1 billion CFU or 1 x 1010 for 10 billion CFU. Many probiotic supplements contain 1 to 10 billion CFU per dose, but some products contain up to 50 billion CFU or more.

Many manufacturers list the CFUs in a product in addition to total microorganism weight on the Supplement Facts label. Because probiotics must be consumed alive to have health benefits and they can die during their shelf life, users should look for products labeled with the number of CFU at the end of the product’s shelf life, not at the time of manufacture. When you see a statement indicating a level of CFUs at the time of manufacture, expect what you ingest will be less than the label claim. Be aware if your label states this: “Formulated with 100 billion CFU at time of manufacturing, loss may occur over time.” Only living probiotic microorganisms can meet the benefit claims made by the manufacturer. In every case, a bottle of supplements sitting in a hot delivery truck, mailbox, front porch, etc. is not going to meet the expectations of the consumer, nor will it have viable, alive microorganisms left after such treatment and handling. One idea to reinforce to your customers is to reassure that none of your products have ever sat in a hot truck or mailbox.

Responsible manufacturers know the stability of their products and provide overages at manufacture as well as test the stability of the manufactured product through the stated shelf life in the packaging of the probiotic.

There are other distinctions in probiotic manufacturing including the requirement to identify genus, species, and strain, in addition to ideally, the quantity of each strain, so it’s important that the probiotic manufacturer know what they’re doing.

As in omega-3s, stability testing is important to ensure the product meets claims throughout distribution and sale. For probiotics, this testing should be conducted under the same temperature conditions as the recommended storage conditions on the finished product label and the product and packaging provided to the consumer should be used to provide an equivalence to the consumer experience.

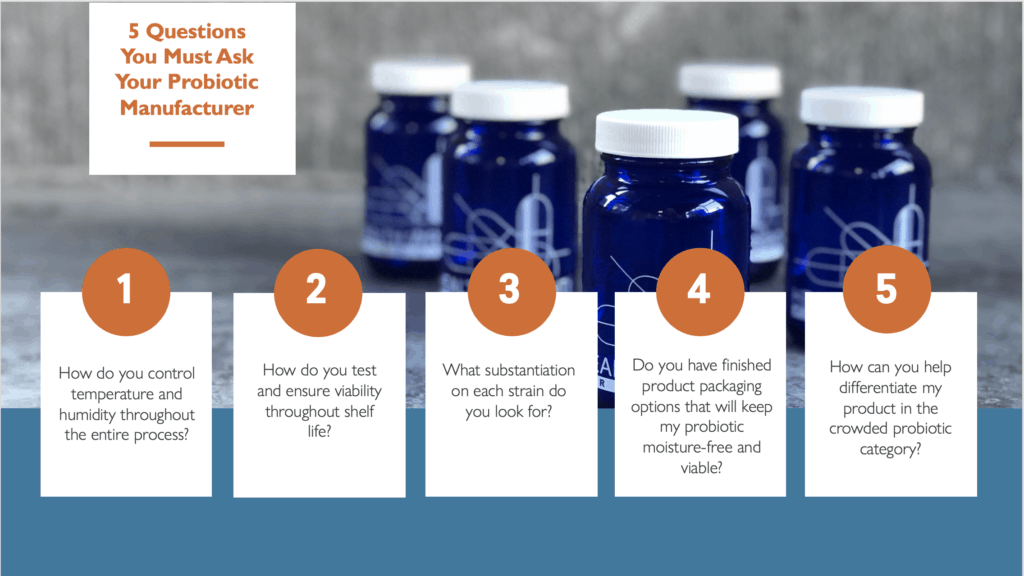

With all of this information comes the realization that the manufacturing due diligence is extremely important in recommending or selecting a probiotic. There are resources available like these “5 Questions you should ask your probiotic manufacturer” from Health Wright Products (disclosure, I am currently the CEO of Health Wright Products).

In the omega-3 category, the standard setting body is the Global Association for EPA and DHA omega-3s (GOED). In operation since 2002 when it first established a monograph and quality control tools for the category, it has grown to be the true global voice of the category, representing brands and ingredient players. Thecurrent monographwas updated a couple months ago and any decent, compliant manufacturer knows that in order to ensure these specifications are met, storage and handling are critical. In the specific case of omega-3s, exposure to high temperatures will cause oxidation and the product will not meet the requirements of the GOED standard. Inferior product on store shelves is not only a bad consumer experience, in this case, it is a sensory hit as well.

In addition to certain ingredient categories, some product formats also don’t store well in elevated temperatures. Both softgels and gummy format products are vulnerable with the former simply melting, and the latter getting really sticky. In fact, even with nominally well-handled products, you can sometimes see clumping in the bottle.

The Natural Products Retailer has the ability to conduct the necessary due diligence on behalf of the consumer to ensure the product purchased has the highest likelihood to be effective. In fact, it’s the responsibility of the retailer and a huge opportunity, in these sensitive categories, to truly differentiate. Amazon has not proven willing to protect dietary supplements any differently than how they protect shoes or dog leashes. Amazon customer service representatives will allow the customers to return product, but they are just as likely to get advice like “bang it on the counter” or “shake it” from theAmazon Ask Questions page.

While it may work from time to time, it goes without saying, a dietary supplement is not going to be made effective by being put in the refrigerator and given a “few hard shakes.” Through increased awareness and transparency, we can improve our product offerings and confidence.

References

- Ozen M, Dinleyici EC. The history of probiotics: the untold story. Benef Microbes. 2015;6(2):159-65. doi: 10.3920/BM2014.0103. PMID: 25576593.

- Hill C, Guarner F, Reid G, Gibson GR, Merenstein DJ, Pot B, et al. The International Scientific Association for Probiotics and Prebiotics consensus statement on the scope and appropriate use of the term probiotic. Nat Rev Gastroenterol Hepatol 2014;11:506-14. [PubMed abstract]