Michael D. Levin, Founder of Health Business Strategies, LLC, noted: “Economic adulteration and low-level contamination represent very real supply chain concerns with all commodities, including botanical and other dietary ingredients regulated by FDA. Ingredient buyers are the ‘Guardians at the Gate,’ who are responsible for approving the use of ingredients for manufacturing. Though this problem is believed to be infrequent, it does happen. Our proposed solution empowers all responsible buyers and suppliers to unite in support of this effort to stop the potential for resale of irreparably defective ingredients through contractual obligations that fairly protect the economic interests of both parties.”

Health Business Strategies, LLC, is a natural products industry consulting firm. BAPP collaborated with the firm to produce the draft contract and SOP template. The documents were produced with input from members of FDA, the NIH, dietary supplement manufacturers and suppliers, and analytical laboratories. BAPP received 106 substantive comments in 2019 from industry stakeholders on the original contract and SOP, which were used to inform the revised draft. The documents now include:

- Expanded and clarified sections on definitions and dispute resolution

- An FAQ document addressing many of the comments received during and after the first public comment round

- A new Three-Party Non-Disclosure Agreement for use by the buyer, seller, and analytical lab

Related: SHP Publishes Sustainability & Regenerative Practices Toolkit BAPP Publishes Adulterants Bulletin on Milk Thistle ABC: Record-Breaking Herbal Sales Predicted for 2020

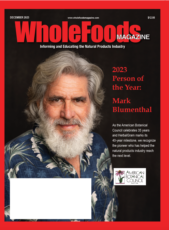

“We are inviting input from a wide array of stakeholders to shape these final tools for widespread industry adoption to help solve a known supply chain issue that sometimes occurs,” said Mark Blumenthal, Founder and Executive Director of ABC and Director of BAPP. “Implementing these proposed best practices contract and SOP templates represents a strong measure by responsible industry members to enhance their ability to more effectively control the ingredient supply chain. The SOP helps to ensure that consumers can purchase properly labeled herbal products with authentic ingredients.”Blumenthal added that many manufacturers have developed long-term relationships with suppliers who use best practices in compliance with cGMPs to analyze ingredients before releasing them for manufacturing. These manufacturers, he noted, have minimal risk for adulteration, although the risks are real. Those buying from a company they have never worked with, however, should “maintain appropriate vigilance.”

“This voluntary industry self-regulatory initiative is intended to empower dietary supplement manufacturers to prevent the resale of defective ingredients that are irreparable; that is, they cannot lawfully be made acceptable for any use in consumer products,” added Blumenthal. “For ten years we’ve been alerting industry members about specific botanical materials that we have confirmed as being subject to adulteration and also which analytical methods are most robust and fit for purpose to detect such adulteration. Now we are counseling industry members on the best practices to prevent irreparably defective materials from remaining in the supply chain.”

“In short,” said Stefan Gafner, Ph.D., Chief Science Officer of ABC and Technical Director of BAPP, “we are helping industry to prevent adulterated ingredients from being rejected by one company, only to be resold by an unethical supplier to another company.”